Most industrial foundations do their task without excitement, right up till they do certainly not. The instant a slab pops all over a cavalcade line, or even a tilt-wall board creeps away from plane after a heavy storm, the discussion improvements coming from routine upkeep to lots roads, soil behavior, and just how to relocate troops safely to something that will definitely certainly not compress even further. Protection piles, helical piles, as well as micropiles rest at the heart of that chat. Each body has a character, a technique it engages the ground, and a set of details that make a decision whether a repair works for decades or even needs to have a second attempt.

I have developed as well as put up all three devices under medical centers that could certainly not close, under information facilities where vibration resistance was actually determined in thousandths of an inch, and in precarious back roads responsible for historical block exteriors. The best selection normally stems from getting married to geotechnical truth along with constructability, after that confirming ability in the field. The segments below break the subject down the method our team manage it on energetic ventures, certainly not in theory.

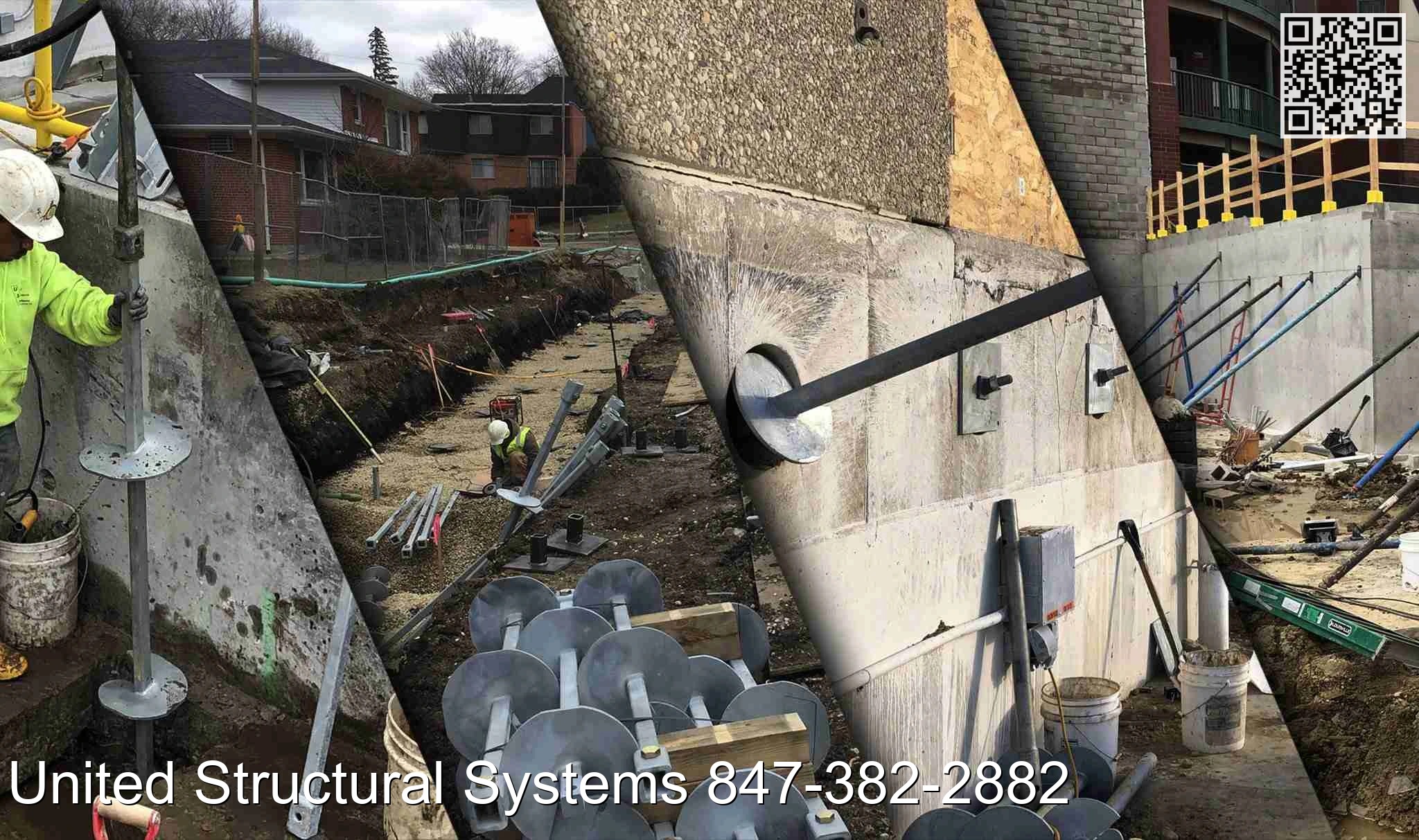

Where protection stacks fit in the commercial toolkit

Commercial resistance pile setup addresses a straightforward trouble: transactions structure tons through flimsy, compressible dirts into something stiffer listed below. Unlike a driven stack with a hammer, a protection or even push pier breakthroughs through gas rams reacting against the property's weight, jacking steel portions until recommendation protection reaches an indicated power. That makes them superb for structural foundation repair where negotiation has currently happened and also you need each brand new assistance and the option to lift.

Helical piles address a related issue in a different way. Their coil plates partitioned the ground at a consistent sound, converting torque in to central capability. They function when you may not react versus existing body weight, when you need to have pressure capability, or when dirts are sensitive to resonance. Micropiles use high-strength steel and also grout to hold load mostly through connect along their size. They are the plastic surgeon's resource for strict internet sites, overhanging space limitations, or heterogeneous soils where a bored, grouted component supplies predictability.

These 3 units, alongside helical tieback anchors for sidewise restraint, cover very most commercial foundation stabilization circumstances. A falling short slab-on-grade at a retail container may prefer resistance piles below quality beams for vertical tons as well as helical tiebacks to bandage an accepting wall structure. A brand new mezzanine in an industrial plant could ask for commercial helical pile installation because you may string equipment between live process lines without a crane. Micropiles usually gain listed below existing elevator cores, smokestacks, and also health centers where resonance as well as sound should be minimal.

Soil regulates the conversation

Ignore the dirt at your risk. I have actually observed projects try to use helical anchors in collapsible loess that went delicate after rainfall, or even resistance piles in a light, steel-framed design that just could not deliver sufficient response. A great subsurface investigation purchases itself several times over.

What issues very most for these units:

- Stratigraphy and variability. Layered clays over sand, or fills with construction fragments, can easily modify size over a couple of feet flat. On a circulation amenities in southern Indiana, pair of nearby columns behaved differently since a buried leveling trench ran between all of them. We adjusted the heap spans through greater than 10 feets over a 40-foot gulf once the evidence tons said to the story. Shear toughness and also friction slant. Helical piles lean on undrained shear toughness in clay-baseds and also on friction in sands. Torque-to-capacity correlations simply conduct if you know the ground profile. Groundwater and also artesian disorders. Micropiles count on cement bond and canvassing reliability. In moving sands, you may need short-lived casing and a thicker grout mix to stay clear of dilution. Obstructions. Cobble lens, ashes, as well as caliche may stop helical piles chilly or even divert drill cords for micropiles. Resistance piles along with sharp suggestions and high mounting pressures in some cases drill through, however even then you jeopardize heap misalignment without careful guidance.

Design fundamentals that maintain you out of trouble

Capacity, rigidity, as well as redundancy separate durable deep foundation repair from a Band-Aid. I have a tendency to come close to the concept in 3 layers: geotechnical capacity, structural adequacy of the heap system, and also weight move by means of braces as well as existing concrete.

Geotechnical capacity. For protection stacks, many capacity originates from end bearing at the recommendation the moment you mount into a dense coating or even rock. The area hoisting stress provides a direct pathway to validating utmost capability, along with an aspect of safety and security put on determine allowed payload. For helical piles, capacity is actually an amount of helix bearing areas or even derived from twist relationship (common worths vary 7 to 12 in-lb every ft-lb for square-shaft as well as design of helical pile foundations round-shaft devices, relying on manufacturer and soil). Micropiles depend upon grout-to-ground bond along a determined span, commonly 60 to 200 psi for clays as well as 200 to 400 psi for sands and also crushed rocks, along with much higher market values in stone sockets.

Structural ability. The steel poles as well as braces should withstand the required tons with suitable security aspects and deterioration allotments. A typical trap is actually over-reliance on torque worths to announce a helical pile "excellent" while failing to remember that the shaft itself possesses a distorting restriction in delicate clay-baseds under compression. Make use of stiffer round-shaft helicals, sleeves, or even grout pillars where fastening is a risk. For micropiles, inspect the steel core in strain and also squeezing, the grout physical body in squeezing, and also composite action with studying if it remains.

Load transmission to the framework. Brackets concern. A retrofit bracket for commercial foundation repair requires sufficient bearing and also embedment into the existing ground or even grade shaft to prevent boxing or splitting. Where groundworks are slim or even riddled with rebar disputes, our company either incorporate nearby thickening, sew brand-new grade shafts, or spread bunches over numerous stacks at lesser individual capability. For pieces, I choose to avoid slab-only brackets as well as as an alternative cut back and also tie right into a shaft or even brand-new boat dock limit. Slabs are unsatisfactory load transmission aspects unless created as such.

Choosing between protection, helical, as well as micropiles

Cost per heap is the incorrect metric. Price per kips of validated ability at company payloads, provided in the room and also routine you in fact possess, is a much better lens.

Resistance heaps shine when the establishment is massive good enough to supply reaction and also when end bearing can be gotten to in an affordable intensity. They are actually excellent for deriving columns, tilt-wall doors, and hefty stonework. They likewise enable measured airlift throughout installment. The weakness: a lightweight building may certainly not permit you activate ample mounting force, as well as soft layers over dense levels may trigger long pile durations along with improving cost.

Helical heaps lug squeezing and also stress, mount quickly, and also deliver clean QA using torque. They stay away from vibration, making them perfect for healthcare facilities, laboratories, and data facilities. They despise rubble fills and also cobbles, which can easily twist coil plates or slow penetration. Square-shaft helicals offer much better torsional strength in hard clays, while round-shaft piles give rigidity in squeezing and lesser buckling risk in delicate soils. Helical tieback anchor units are the sidewise buddy for maintaining wall structures, cellar walls, as well as supported excavations. Commercial helical tieback anchor installation helical pile foundations commonly features proof filling to 120 to 150 percent of concept stress and lock-off at company load.

Micropiles go where absolutely nothing else can. Little gears travel through 8-foot doors. Canvassed exploration takes care of collapsible soils. Cement connect helps make capacity less sensitive to separate obstacles. They are actually versatile for deep foundation repair under existing structures, however component and also mobilization expenses every heap could be greater. In stone, tight pressure-grouted outlets supply remarkable capability in cramping footprints.

Installation realities that choose success

On a retrofit at a clinical office complex, our team had 5 weekends to support as well as elevate a cleared up section where differential had reached out to virtually 1.5 ins. The strategy mixed resistance piles for airlift and helical tiebacks to counter minor lateral ground tension on a cellar wall structure. What created it work was actually not ingenious mathematics, it was logistics and also sequencing.

Access. Think of just how equipment gets in and also out, where spoils go, and how to take care of slurry or even grout in occupied homes. Commercial micro pile installation typically requires a clean cement vegetation setup, spill control, and washout management. Helical pile rigs are active, yet you still need to have a course for 10 to twenty feet top areas or even spliced sectors. Resistance stacks need a very clear face at the footing and room to stage hydraulic pumps as well as gauges.

Measurement and also tolerances. For resistance heaps, utilize calibrated evaluates as well as file hoisting forces and lift increases. Footing lift should be actually slow-moving and also uniform, often a handful of millimeters every successfully pass around a number of heaps to stay away from fracturing. For helical piles, view both twist and pitch every reformation to validate accurate development, not dirt disruption. For micropiles, screen grout take and stress; a quick decrease might suggest a space or even a loss region that calls for packers or even staged grouting.

Obstructions and also changes. Think at the very least 10 to 20 percent of places will deviate from consider existing properties. Always keep alternative stack inputs the script. On one storage facility job where helical piles fulfilled bouldery frosty till, our company shifted a third of the areas to micropiles along with brief rock outlets and kept the timetable through mobilizing a portable drill midweek.

Noise and also resonance. Helical piles and micropiles get along to vulnerable renters, but taught work still produces some audio. Resistance pile installment develops visible hydraulic pump noise as well as can easily resonate local aspects during lift. Interact with tenants, schedule loud periods properly, and set up resonance displays near delicate coatings or even devices if limits are tight.

Capacity verification and quality control on site

You do certainly not receive what you layout; you acquire what you evaluate. In commercial helical pile installation, the torque log is your first top quality inspection, however I still as if to verification lots a representative sample, specifically in layered profile pages where torque relationship may wander. Common practice: load to 1.5 to 2.0 opportunities concept, carry and also notice creep. For pressure helical anchors as well as tieback anchors, verification as well as, for some, performance examinations are basic, with lock-off at service tons after satisfactory creep.

Resistance heaps offer instant comments by means of jacking tension and also displacement. We track hoisting pressure versus small activity to see to it our team are actually not just compressing delicate strata without getting to end bearing. After lock-off, a lift-readiness inspection makes certain piles share load. If one area presents big activity at modest pressure, suppose a local area weak spot as well as incorporate a heap or even rise embedment at adjacent points.

Micropiles are actually evaluated via grout take, connect length, and, on decided on stacks, compression or even pressure testing. Where our experts anticipate higher ability from connect in thick sand, our team often include a verification pile with an Osterberg cell or even a traditional fixed load test. It is actually certainly not inexpensive, yet on projects along with hundreds of micropiles, one neglected layout belief costs more than a well-instrumented test.

Structural information that wait together

Most breakdowns I have explored in base repair work did not begin in the ground, they started at the user interface. Brackets that broke a ground, anchor bolts that gave throughout airlift, or welds that clipped coming from eccentricity may undermine or else sound piles.

For resistance pile braces, dispersed the response. I choose braces that commit beneath the footing with a seating plate and mechanical connection instead of bearing upon a slim slant. Where existing footings are shallow, our company center or even potato chip wallets, area improving pegs along with appropriate embedment, and also directed a cement buttocks to provide a well-maintained bearing area as well as to distribute tons into the footing. On greatly rich columns, our experts sew a new heap hat around the ground, association right into the existing along with epoxy pins, as well as land multiple stacks in to that hat to share load.

For helical piles assisting new steel columns, line up the heap head along with the column load course, prevent large eccentricities, and style for each squeezing as well as uplift if the make use of can modify. In coastal applications, corrosion allotments and also hot-dip galvanizing stretch life span, and in threatening soils our company add propitiatory density or even cathodic security per the geotechnical report.

For micropiles, tons transmission develops at a stack limit or level shaft. The steel bar or casing ventures in to the limit, cultivated by bond and also mechanical equipment. We check bar advancement, ensure enough shear abrasion throughout any building joint, and consist of confinement strengthening to take care of powerful strut-and-tie paths.

Lifting cleared up designs without producing brand new problems

Many managers request airlift to recover doors, windows, as well as piece slopes. Lift is achievable with protection piles as well as, sometimes, with helical piles utilizing hoisting scalps. The adversary resides in the rate as well as the pattern.

We beginning through determining what should move all together. On a two-story workplace wing, our team elevated exterior level shafts as well as interior pillar footings in a teamed up sequence, just 1/8 inch every lift pass, smoothing by means of 6 to 12 piles in a loophole. A laser device amount tracked loved one movement. Inner parts completes broken at a handful of joints, but significant distress was actually stayed away from. As soon as target altitude is reached out to or the structure ceases responding without extreme pressure, our company lock off. Anticipate partial rehabilitation, not perfectness, when brittle masonry, solid utilities, or differentially rigid frameworks withstand consistent movement.

Slabs need to have special care. Residential technique sometimes mounts slabs straight with little piers. On industrial pieces sustaining shelfs or assembly-line production, I highly choose cutting in grade shafts or even putting in under-slab stack hats to pick up loads. Pieces on their own usually tend to rebound and also break under factor jacking. When piece jacking is actually unavoidable, use more aspects at lesser airlift every point, and look at polyurethane injection to load voids after architectural airlift, certainly not as a primary building fix.

Helical tieback anchors for sidewise stability

When cellars bow or when ground stress improves after drain breakdowns, helical tiebacks provide a clean, testable means to incorporate sidewise resistance. Commercial helical tieback anchor installation generally involves exploration at a shallow slant with the wall surface, evolving coils beyond the active wedge in to seasoned ground, and afterwards worrying the anchor versus an interior grain or outdoor plate.

Key selections feature the support angle, helix setup, and also connection size beyond the breakdown aircraft. Evidence testing matters a lot more here than almost anywhere since stress creep tells you specifically what you possess. For historical brick or unreinforced masonry, our team stay clear of factor loads on the wall surface by including continuous wales or by spreading response along with steel structures. In waterfront apps, deterioration details rival architectural ones; indicate dual oxidation protection if service life intendeds go beyond a couple of many years in chloride environments.

Managing deterioration and durability

Deep groundwork repair service is typically executed on aging buildings that still possess decades to provide. That means oxidation concept is certainly not a footnote. Helical piles and also supports can be found in plain and galvanized variations. Galvanizing adds instant defense; sacrificial thickness arithmetics include lasting confidence; in aggressive soils with low resistivity or even higher sulfates, consider epoxy coatings or even cathodic defense. Protection piles are normally steel pipe or even cylinder sectors; our company spec oxidation allotments and also, where needed to have, fill with cement grout to minimize indoor deterioration and also rise stiffness.

Micropiles supply a baked-in conveniences: a grout cover around steel delivers alkaline security. Dual rust defense, with central attorneys enclosed in cement within a bumpy coat or case, is regular in DOT practice for high-duty cycles. For commercial job near utilities or in deicing-salt hefty areas, stealing those DOT information is funds well spent.

Permitting, testing requirements, and also records that take on scrutiny

Authorities having jurisdiction try to find familiar standards. For helical piles and supports, ICC-ES reports and AC358 approval criteria quick guide style as well as QA, and many makers publish ESRs that connect twist to capability within described restrictions. For micropiles, FHWA suggestions as well as PTI referrals provide bond worths, testing methods, as well as layout systems. Protection piles are much less standard across makers, which places the responsibility on designers and installers to chronicle mounting pressures, lift, as well as section information along with clarity.

On sizable projects, a third-party exclusive assessor incorporates reputation. Our experts commonly give a package deal that consists of pile logs, examination outcomes, as-builts with coordinates as well as altitudes, weld as well as bolt qualifications, grout mix tickets, and also gradation certifications for twist indications and ports. When questions come years later, this file addresses them without guesswork.

Integrating gap repair work and waterproofing along with building work

Owners frequently request for foundation crack repair in the exact same breathing as centered foundation work. Epoxy treatment can sew architectural cracks after tons courses are repaired, while polyurethane injection or hydrophilic waterstops address leakage. Pattern matters. Support first with commercial foundation stabilization methods, assist if necessary, after that infuse. If you infuse a moving gap, you will chase after cracks forever.

Exterior drainage still matters. A row of excellent stacks are going to not maintain a wall structure dry out if roofing leaders unload water at the foundation. Our experts include swales, downspout extensions, or perimeter drains where needed to have and, on sensitive interiors, a negative-side covering or interior drainpipe tile to relieve hydrostatic pressure.

Pricing and also organizing realities

Unit rates vary by area, maker, as well as extent, so any sort of numbers must be actually treated as ranges, certainly not quotes. In lots of markets:

- Helical stacks for business make use of typically fall in the ballpark of moderate 4 figures every heap put in at typical sizes, with twist surveillance and also conventional heads. Tension-rated supports and tiebacks are similar on a per-capacity basis. Resistance stack prices depend heavily on deepness to finish bearing and also bracket intricacy. Where bearing is actually shallow and also the construct is actually heavy, they compete effectively. Where bearing is deep, micropiles or helicals might hammer all of them on production rates. Micropiles come with greater use and also material costs per piece, but one micropile can substitute numerous smaller sized components when capacity is high, particularly along with rock outlets or long connection zones.

Schedule rests on accessibility and testing. A six-pile groundwork at a solitary ground might take 2 to 3 times consisting of digging, installation, airlift, and also backfill. A hundred-pile project can operate many weeks with overlapping staffs. Micropiles call for cure opportunity for cement prior to complete lots testing or limit puts, commonly 2 to 7 times relying on mix as well as temperature.

A short field scenario: 3 systems on one campus

On an educational institution laboratory property, our team encountered three distinctive complications. The south wing had actually settled 0.9 inches after an adjacent electrical trench transformed water drainage. The basement wall on the eastern side revealed lateral activity as well as cracking. A brand-new rooftop technical device asked for pair of new interior columns carrying uplift in the course of wind events.

We utilized resistance piles under the south wing grade shafts. The design delivered sufficient response for mounting to over 50 kips every heap, and our team accomplished a 0.6 in even airlift all over nine places over pair of days. For the east wall, commercial helical tieback anchor installation solved the lateral trouble. We punched via slim hallways, verification evaluated each support to 1.5 opportunities concept, and latched off at service. For the internal columns, commercial helical pile installation supplied both compression as well as uplift capability in a precarious roof elevation, with round-shaft helicals to withstand twisting in soft clay. The end result: 3 different bodies, one use, as well as a single as-built document that the facilities crew can easily reference.

Where to start on your project

If you handle or even own an office building with negotiation, leaning walls, or organized building modifications, the most effective upcoming action is actually not selecting an item. It is scoping an examination that integrates a concentrated geotechnical look with a useful constructability testimonial. Request shear strength profiles, groundwater monitorings, and also any type of corrosivity records. Stroll the site with an installer that has commercial knowledge, certainly not just property job, as well as talk by means of gain access to, setting up, and also just how tenants will be actually affected.

From there, opt for in between helical piles, resistance stacks, or micropiles based on dirt, tons, get access to, and the necessity for strain, airlift, or sidewise capability. Devote to field proof with verification examinations and also clear documentation. Fold in foundation crack repair only after stabilization. And also remember that commercial foundation repair does well when the ground reality, architectural details, and also installation specialty line up.

Deep groundwork repair work is not attractive, however when done straight it goes away into the structure and also earns no attention for the next half-century. That is actually the goal.